Manufacturer of high-pressure jetting units "POSEIDON".

The equipment for repair, inspection, cleaning and installation of pipelines.

The equipment for repair, inspection, cleaning and installation of pipelines.

Brend

8-800-555-79-97Сallback

HOME > SECTION > Extremely high pressure hydrodynamic equipment “Poseidon” for 500 - 2,800 bar > 500 - 2,800 bar hydrodynamic equipment “Poseidon” with autonomous drive > Poseidon DT170USCube apparatus series, 170 hp, 1,000-2,800 bar, 15-37 l/min

Manufacturer: ZET-TECHNO (Russia)

Application:

Wide scope of application in heavy industry, agriculture, housing and utilities sector, and construction:

Price: руб. In stock

| Water supply | Technical water, 60 °С max. (45°С max. is recommended) | ||

| Pump options, bar@l/min | 1,000 bar 37 l/min | 1,400 bar 29 l/min | 2,800 bar 15 l/min |

| Pressure adjustment | By means of jet caliber (standard) or high pressure regulator (optional) | ||

| High pressure pump | Horizontal, crank-and-rod, with stainless steel unit and integrated plunger cooling system, T-300 Gardner Denver (USA) | ||

| High pressure pump rotation rate | 600 rpm | ||

| High pressure pump protection | Frame-mounted booster pump, pump dry running protection, high pressure safety valve with rupture disc | ||

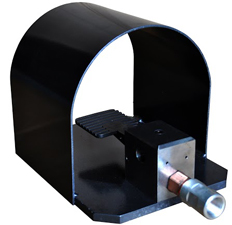

| Type of high pressure pump drive | Belt-type configuration with fencing | ||

| Motor | Six-cylinder diesel motor John Deere (USA) featuring fluid cooling, turbocompressor, and user-friendly control console.

| ||

| Fuel tank | 60 l | ||

| Water tanks | 200-litre surge tank made from aluminum or stainless steel fitted with filling control valve and drainage gauge, access door for cleaning. Upon request, an aggregate is completed with 300 – 3,000 litre water tanks, as per installation conditions. | ||

| Design | Standard or extended frame, mounting on dolly, trailer, chassis, container, heated container | ||

| Weight | 2,000 kg | ||

| Dimensions, LхWхH | 2,250x1,750x2,000 mm | ||

| Warranty | 5 years for motor. 1 year for apparatus, 2 years – extended warranty. | ||

Frame-mounted high pressure equipment “Poseidon” is a powerful solution for industrial cleaning of pipes and surfaces. Compact and user-friendly design, solid frame, reliable components make the equipment “Poseidon” universal and reliable apparatus for operation in all fields of industry.

High pressure equipment of this series feature an integrated tank water and do not depend on the water supply network parameters. Simply provide for clean technical water, at that pressure and input flow can be any!

The equipment can be mounted on a container, specialized vehicle (refer to Chapter “Specialized Vehicles”), trailer.

We perform turnkey installation on any chassis requested by a customer – ranging from trailer to van, special vehicles not being an exception.

Features:

Pumpс T-300M/H/UH

T-300 pump consists of two main parts: power unit and hydraulic one. The power unit comprises crankshaft, rods and pistons; it is intended to convert revolving motion from the motor to reciprocating motion of plungers. T-300 pump is offered together with three standard hydraulic units: “M” standard – for pressure of 552 – 1,034 bar, “H” standard – for pressure 1,034 – 1,379 bar, and “UH” standard – for pressure of 2,759 bar.

Hydraulic unit:

All hydraulic units Partek from Gardner Denver have several features allowing to considerably increase service life and repairability.

Standard «L»

Pressure of up to 1,034 bar (T-300M)

“L” standard represents a conventional industrial standard for hydromonitors. Simple structure allows for easy and quick replacement of valves, plungers and seals even in field conditions. Plungers are made of stainless steel with special coating and resistant to temperature extremes.

“L” standard represents a conventional industrial standard for hydromonitors. Simple structure allows for easy and quick replacement of valves, plungers and seals even in field conditions. Plungers are made of stainless steel with special coating and resistant to temperature extremes.

In-line arrangement

1,034-1,379 bar (T-300H)

1,379-2,759 bar (T-300UH)

Horizontal, in-line arrangement of inlet and outlet valves precludes occurrence of wave interference effect, which allows to operate at pressures over 1,000 bar. Unique technology of repair of valves and valve seats adds hundreds of hours to a pump service life at less costs. A plunger surface is coated with hard polished tungsten carbide, which ensures maximum extension of service life of plungers and seals.

Horizontal, in-line arrangement of inlet and outlet valves precludes occurrence of wave interference effect, which allows to operate at pressures over 1,000 bar. Unique technology of repair of valves and valve seats adds hundreds of hours to a pump service life at less costs. A plunger surface is coated with hard polished tungsten carbide, which ensures maximum extension of service life of plungers and seals.

Power unit:

Accessories:

Warranties:

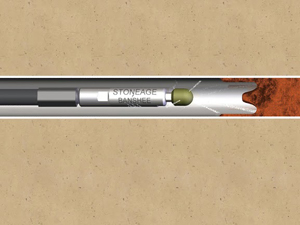

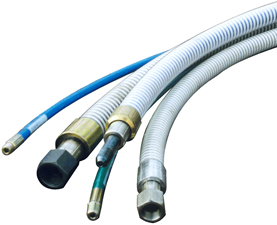

Rotary tip for cleaning of surfaces |  Rotary tips for cleaning of pipes and heat exchanger tubes |  Jet for cleaning of surfaces |

Pedal for convenient work with flexible lances |  Hoses and flexible high pressure lances |  Gun with shoulder thrust |

DT170USCube-2800-15-JD

Ultra high pressure cleaner POSEIDON on Cube frame (John Deere 170hp, pump Gardner Denver (USA), integrated 200-litre stainless steel water tank, without hose, gun and nozzles)

Working weight, kg

2000

| Water supply | Technical water, 60 °С max. (45°С max. is recommended) | ||

| Pump options, bar@l/min | 1,000 bar 37 l/min | 1,400 bar 29 l/min | 2,800 bar 15 l/min |

| Pressure adjustment | By means of jet caliber (standard) or high pressure regulator (optional) | ||

| High pressure pump | Horizontal, crank-and-rod, with stainless steel unit and integrated plunger cooling system, T-300 Gardner Denver (USA) | ||

| High pressure pump rotation rate | 600 rpm | ||

| High pressure pump protection | Frame-mounted booster pump, pump dry running protection, high pressure safety valve with rupture disc | ||

| Type of high pressure pump drive | Belt-type configuration with fencing | ||

| Motor | Six-cylinder diesel motor John Deere (USA) featuring fluid cooling, turbocompressor, and user-friendly control console.

| ||

| Fuel tank | 60 l | ||

| Water tanks | 200-litre surge tank made from aluminum or stainless steel fitted with filling control valve and drainage gauge, access door for cleaning. Upon request, an aggregate is completed with 300 – 3,000 litre water tanks, as per installation conditions. | ||

| Design | Standard or extended frame, mounting on dolly, trailer, chassis, container, heated container | ||

| Weight | 2,000 kg | ||

| Dimensions, LхWхH | 2,250x1,750x2,000 mm | ||

| Warranty | 5 years for motor. 1 year for apparatus, 2 years – extended warranty. | ||

DT170USCube-2800-15-JD

Ultra high pressure cleaner POSEIDON on Cube frame (John Deere 170hp, pump Gardner Denver (USA), integrated 200-litre stainless steel water tank, without hose, gun and nozzles)

Working weight, kg

2000

143500, Moscow region, Istra,

Zheleznodorozhnyy proezd, 5B