Manufacturer of high-pressure jetting units "POSEIDON".

The equipment for repair, inspection, cleaning and installation of pipelines.

The equipment for repair, inspection, cleaning and installation of pipelines.

Brend

8-800-555-79-97Сallback

HOME > SECTION > Extremely high pressure hydrodynamic equipment “Poseidon” for 500 - 2,800 bar > 500 - 2,800 bar hydrodynamic equipment “Poseidon” with electrical drive > Poseidon E75USCube apparatus series, 75 kW, 1,000-2,800 bar, 15-37 l/min

Manufacturer: ZET-TECHNO (Russia)

Application:

Wide scope of application in heavy industry, agriculture, housing and utilities sector, and construction:

Price: руб. In stock

| Water supply | Technical water, up to 50 °С (up to 45°С is recommended) | ||

| Pump options, bar@l/min | 1,000 bar 37 l/min | 1,400 bar 29 l/min | 2,800 bar 15 l/min |

| Pressure adjustment | With the use of jet bore (basic) or high pressure regulator (optional) | ||

| High pressure pump | Horizontal, crank-and-rod, with unit made of stainless steel and built-in plunger cooling system Gardner Denver T-300 (the US) | ||

| High pressure pump rotation rate | 600 rpm | ||

| High pressure pump protection | Frame-mounted booster pump, protection against dry running, safety valve with rupture disc | ||

| Type of high pressure pump drive | Belt-drive configuration with fencing | ||

| Motor | Asynchronous electromotor (Russia or Belarus), explosion-proof design is available. Power – 75 kW (380 V, 50 Hz). | ||

| Motor control | Magnetic starter, phase control, current overload protection, light indication. If requested by a customer, it can be fitted with a star-delta starter connection to reduce load on a network upon energizing. | ||

| Water tanks | 230 litre expansion water tank made of aluminum or stainless steel featuring filling control valve, discharge gauge, and access door for cleaning. If requested individually, 300 – 3,000 litre water tanks can be supplied and assembled as per conditions. | ||

| Design | A bulky or standard frame, mounting on a dolley, trailer, chassis, container, heated container | ||

| Weight | 1650 кг | ||

| Dimensions, LхWхH | 1800х1400х1485 mm | ||

| Warranty | 1 year, extended warranty – 2 years | ||

Frame-mounted high pressure equipment is a powerful solution for industrial cleaning of pipes and surfaces.

High pressure apparatus of the given series utilize built-in water tank and therefore do not depend on water supply line parameters. Simply supply clean technical water, pressure and input flow can be any!

As an alternative, mounting into/on a container, special-purpose vehicle (refer to section “Special vehicles”), or trailer is available.

We provide turnkey installation works on any chassis – ranging from a trailer to caravan, special vehicles being no exception – at the request of a customer.

Особенности:

Pump Gardner Denver T-300M/H/UH:

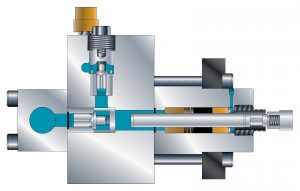

T-300 pump consists of two main parts: power unit and hydraulic one. The first comprising crank shaft, connection rods, and pistons is intended to convert motor rotation to back-and-forth motion of plungers. Three standard units for T-300 pump are offered:

Hydraulic unit:

All Partek hydraulic units from company Gardner Denver possess several features allowing to considerably increase their service life and repairability.

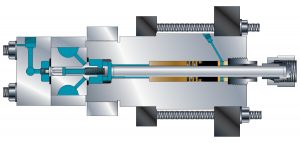

“L” standard

Pressure of up to 1,000 bar(T-300M)

“L” standard is a generally accepted industry standard applied to hydraulic guns. Simple design allows an easy and quick replacement of valves, plungers and seals even in the field. Plungers made of stainless steel with a special coating, unlike ceramic ones, are resistant to excessive temperatures.

In-line arrangement

Pressure of 1,000 – 1,400 bar (T-300H)

Pressure of 1,400 – 2,800 bar (T-300UH)

Due to horizontal, in-line arrangement of inlet and outlet valves a wave interference phenomenon does not occur, which allows operating at pressures over 1,000 bar. Unique technology of valve and seat repair accrues hundreds of hours to a pump life and reduces costs at the same time. The surface of plunger has a polished hard tungsten carbide coating, which allows plungers and seals reach their maximum service life.

Due to horizontal, in-line arrangement of inlet and outlet valves a wave interference phenomenon does not occur, which allows operating at pressures over 1,000 bar. Unique technology of valve and seat repair accrues hundreds of hours to a pump life and reduces costs at the same time. The surface of plunger has a polished hard tungsten carbide coating, which allows plungers and seals reach their maximum service life.

Power unit:

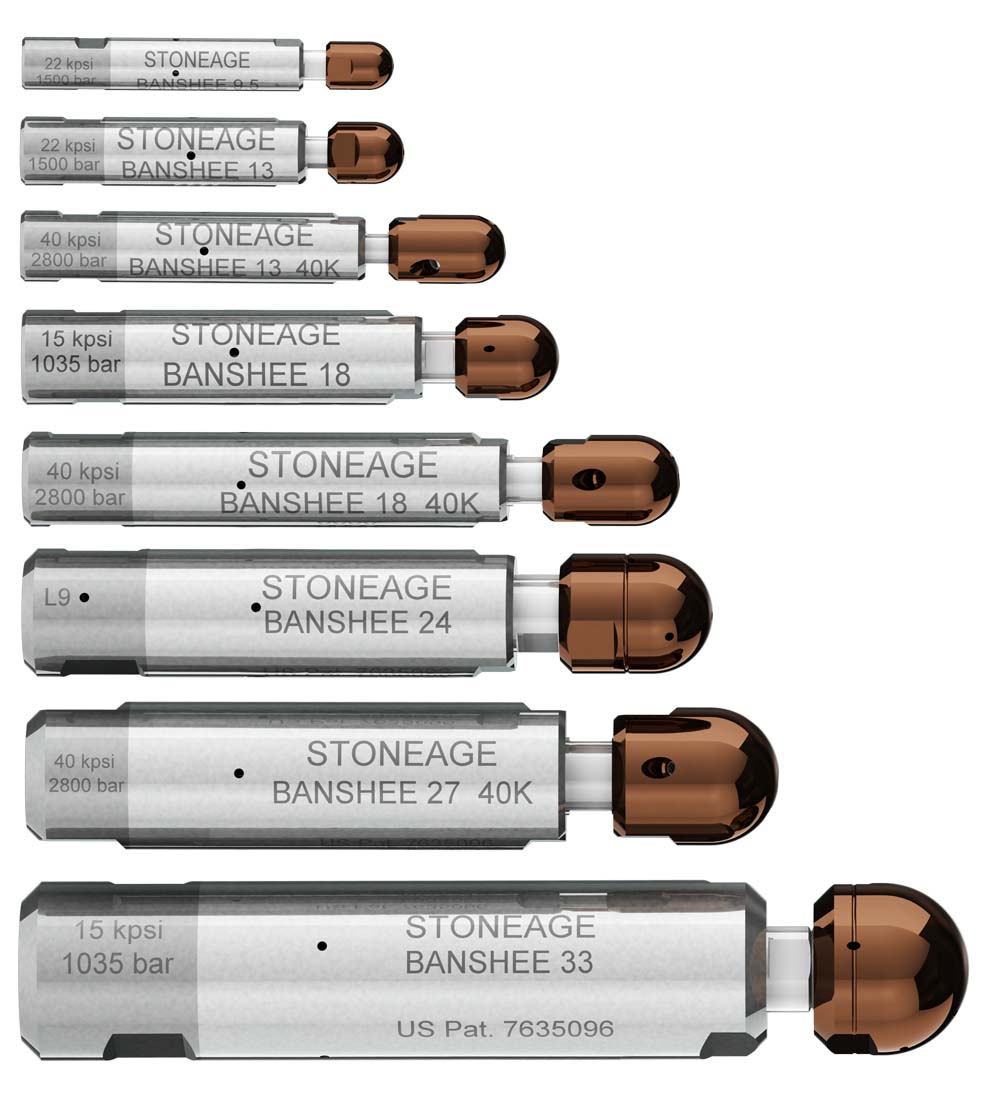

Accessories:

Warranties:

Rotary nose-piece for cleaning of surfaces |  Rotary nose-pieces for cleaning of pipes and heat exchanger pipes |

Jets for cleaning of surfaces |

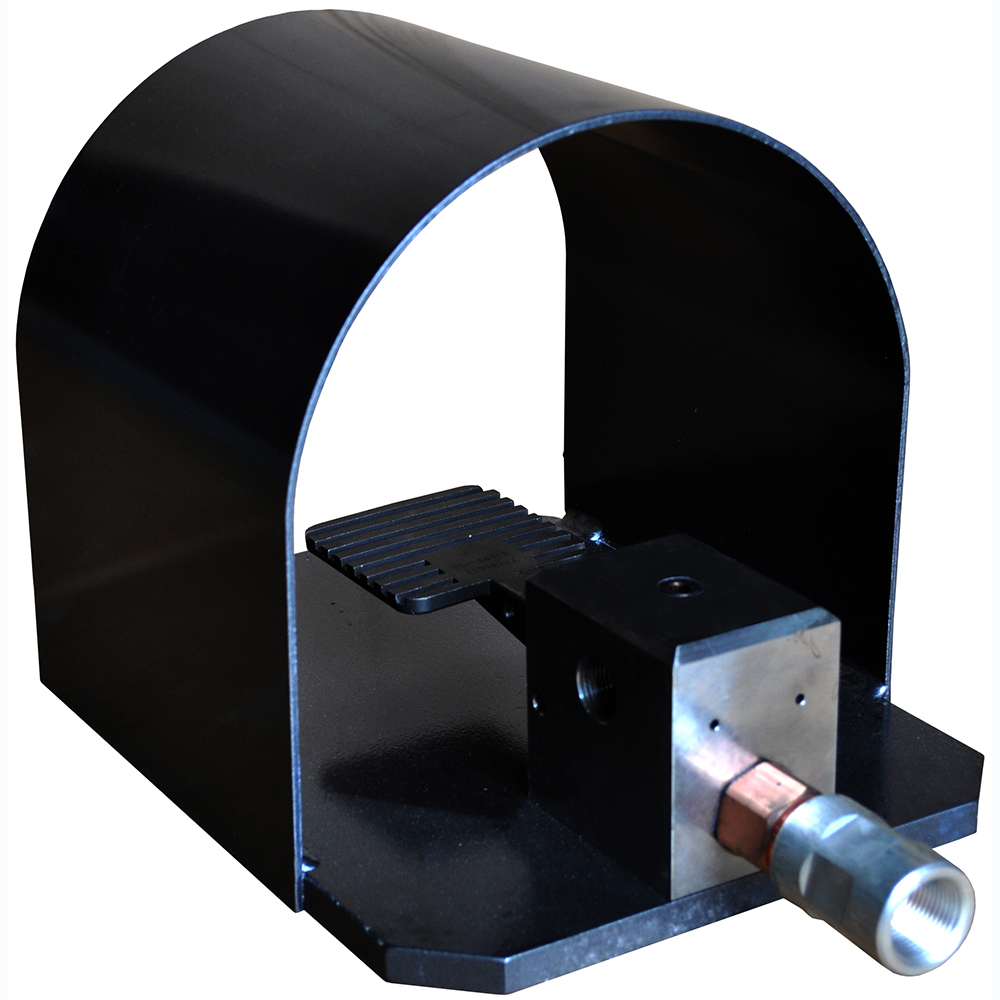

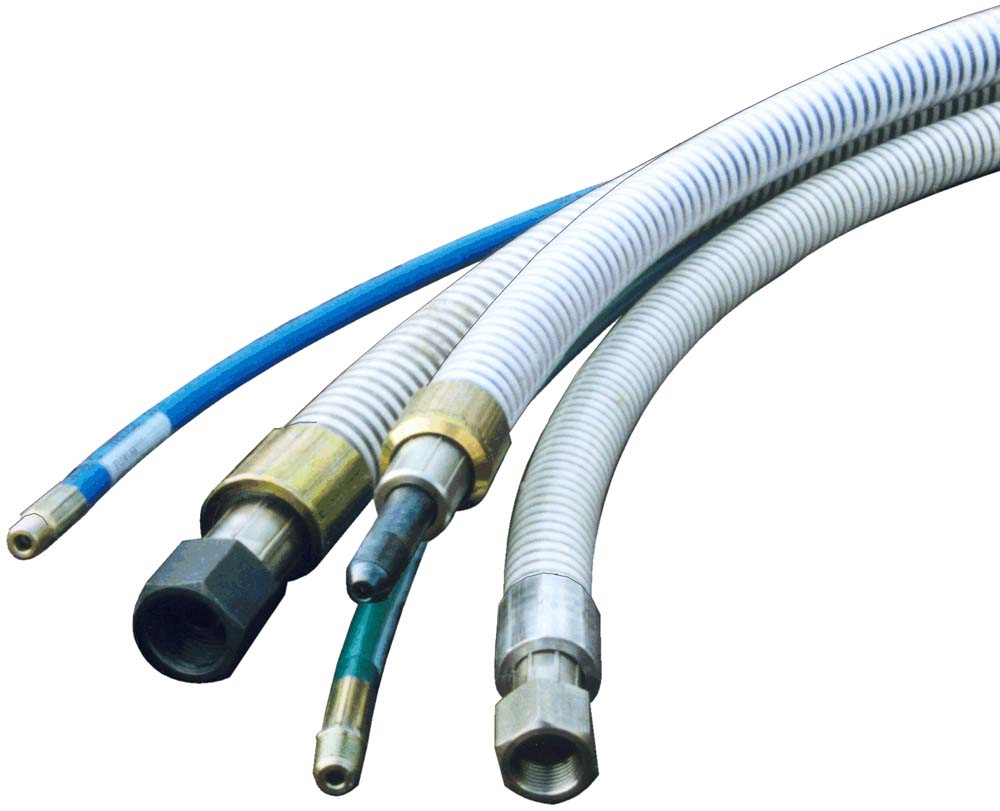

Pedal for convenient work with flexible lances |  High pressure hoses and flexible lances |  Shoulder rest gun |

E75USCube-1400-29

Ultra high pressure cleaner POSEIDON on Cube frame (electro 75kW, pump Gardner Denver (USA), integrated 230-litre water tank, without accessories)

Working weight, kg

1650

| Water supply | Technical water, up to 50 °С (up to 45°С is recommended) | ||

| Pump options, bar@l/min | 1,000 bar 37 l/min | 1,400 bar 29 l/min | 2,800 bar 15 l/min |

| Pressure adjustment | With the use of jet bore (basic) or high pressure regulator (optional) | ||

| High pressure pump | Horizontal, crank-and-rod, with unit made of stainless steel and built-in plunger cooling system Gardner Denver T-300 (the US) | ||

| High pressure pump rotation rate | 600 rpm | ||

| High pressure pump protection | Frame-mounted booster pump, protection against dry running, safety valve with rupture disc | ||

| Type of high pressure pump drive | Belt-drive configuration with fencing | ||

| Motor | Asynchronous electromotor (Russia or Belarus), explosion-proof design is available. Power – 75 kW (380 V, 50 Hz). | ||

| Motor control | Magnetic starter, phase control, current overload protection, light indication. If requested by a customer, it can be fitted with a star-delta starter connection to reduce load on a network upon energizing. | ||

| Water tanks | 230 litre expansion water tank made of aluminum or stainless steel featuring filling control valve, discharge gauge, and access door for cleaning. If requested individually, 300 – 3,000 litre water tanks can be supplied and assembled as per conditions. | ||

| Design | A bulky or standard frame, mounting on a dolley, trailer, chassis, container, heated container | ||

| Weight | 1650 кг | ||

| Dimensions, LхWхH | 1800х1400х1485 mm | ||

| Warranty | 1 year, extended warranty – 2 years | ||

E75USCube-1400-29

Ultra high pressure cleaner POSEIDON on Cube frame (electro 75kW, pump Gardner Denver (USA), integrated 230-litre water tank, without accessories)

Working weight, kg

1650

143500, Moscow region, Istra,

Zheleznodorozhnyy proezd, 5B